A newly completed facility in Vietnam will help Olmix expand its business in Southeast Asia and China as well as accelerate product development in the region, according to Daniele

Marzin, marketing and innovation director.

Daniele Marzi

The plant will start with an initial production capacity of 5,000 tonnes/year, which is enough to supplement five million tonnes/feed. Production can be expanded to up to 15,000 tonnes/year, she added.

The factory, worth over two million euros, will manufacture ingredients and feed additives for Asian markets, such as MShell for enhancing shell and bone quality, Searup, DigestSea, M Tox and more. ASEAD – a range of new generation acidifiers – will debut later in 2018.

Main ingredients such as algae, clays and trace minerals will be shipped from France by the parent company, but some ingredients will be procured locally. The locally procured ingredients will be tested to prevent heavy metal contamination and ensure purity.

The plant is already ISO 9001 certi ed, with FAMI-QS accreditation likely done by 2018. Finished products are quarantined and tested before release in compliance with European feed regulations.

Having a facility in Vietnam will help Olmix improve the freshness of its products for customers while keeping a lid on production and logistic costs.

Olmix is set to launch water soluble immuno-stimulant products derived from algae extracts in Asia. In-depth studies of the product’s mode of action at the molecular level are underway to explain the effect on animal cells.

She added that Olmix is doing research and trials in collaboration with universities in Thailand and Vietnam. Also, validation trials on a commercial scale with various integrators in the region will prove that Olmix products improve customer profitability.

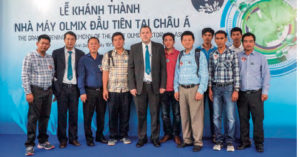

t the recent inauguration, Herve Balusson, group president and CEO, emphasized Olmix’s commitment to safe feed and wholesome food throughout the value chain.

Olmix will be active in both livestock nutrition and plant care in Asia. Newly acquired PRP Technologies’ core competencies are algae and trace elements, and it has a well-established market position in plant and animal nutrition.

The acquisition offers a natural market hedge and is product complementary. Olmix Asia will soon expand its team to develop plant health businesses.

By 2022, Olmix’s revenue from animal nutrition and the growing plant care business will be more balanced.

As well, the recent acquisition of Aroma Celte, a France-based manufacturer of food supplements based on essential oils and algae for humans, will help Olmix develop markets for algae-based food supplements to support human health.

Cutting-edge research

Olmix researchers’ core focus is unlocking the secrets of clay-based biomaterials and algae extracts. Some of the company’s flagship technologies are marine sulphate polysaccharides (MSP®), Olmix Exfoliated Algoclay (OEA®) and Amadeite®.

MSP® are being examined for their potential in biomedical applications and new products that enhance immunity, improve gut heath and feed efficiency.

OEA® is derived from the interaction between algal extracts and montmorillonite clay. The clay structure is modified and its biocatalytic capabilities improved, boosting enzyme activity due to increased accessibility of metallic ions in the clays which serve as cofactors in enzymatic reactions.

Amadeite® organic clay undergoes structural modification as a result of interaction between algal polysaccharides and montmorillonite clay. The clay structure is widened, leading to better adsorption of toxins and heavy metals.

ébastien Balusson, chief operating of cer, (5th left) and Trinh Quang Thanh (2nd left) together with delegates from Cambodia

Meanwhile, Olmix’s technical team in Asia is consulting with customers in Taiwan and Vietnam who are revising their management strategies with the goal of eliminating the need for antibiotics on their farms.

Construction of a second factory to collect and treat red algae in Saint Hilaire De Riez, France is ongoing. The company built its first algae processing plant in Plouenan, northern Brittany in 2013.

Olmix took over Viphavet in 2014 to increase its market coverage in both animal health and nutrition in Vietnam.

Viphavet is a top supplier of vaccines, pharmaceuticals, and biological products for animals. It is GMP-WHO certified.

Olmix has also invested in the firm’s subsidiary Viphalab, whose core focus is veterinary diagnosis, and identification and quantification of mycotoxins in animal feed. The company offers solutions for livestock production, including technical support, training, and vaccination equipment.